What factors will make your next cycling outfit more comfortable? Phil Latz asked four cycle clothing experts to give you tips on some important things to consider.

If you think that cycle clothing is ‘low tech’ compared to bicycle technology, then think again! An amazing amount of design thought, fabric technology and skilled construction goes into making a high quality cycling garment. After hearing from the four cycle clothing experts we interviewed, you’ll also begin to appreciate why there is such a huge price range between budget cycling gear and the top of the range garments. Obviously, every company in this competitive market is proud of their product range, and has unique selling features. However for this story, our experts all agreed to give technical information without ‘plugging’ their own brands. First we spoke to Wally Lancaster, the importer of Pearl Izumi clothing. “Two of the biggest aspects in my belief are fabric and cut,” Wally began.

Fabric

“A lot of products claim to have performance fabric and it has become a bit of a generic term. I believe a performance fabric is one which either offer an advantage from the elements or it performs in a sporting context, in that will allow enough humidity to escape the garment when you’re working hard. Obviously cycling is a high endurance sport, so the performance of the fabric becomes quite important. “Having a fabric that simply dries quickly or wicks moisture isn’t enough. For example, cotton wicks sweat very well away from your body, but obviously cotton won’t then disperse that sweat and have it dry quickly on the surface. “So what I look for in performance fabric is what is called an ‘engineered fabric’. This means you will have varying degrees of fabric from the inside to the outside of the garment that will move moisture and sweat away from your body mechanically, simply by having a larger surface area of fibre on the outside versus that on the inside. “If you can imagine looking at the micro fibres, the micro fibres on the inside are a reasonably thick and loosely packed. Then as you move to the outside of the fabric, the micro fibres are very fine, much more silk like and much more tightly packed. “If you were to take a square centimetre of the inside fabric and see how much moisture it could soak up, then do the same for a centimetre of the outside fabric, you’d find that the outside fabric can hold a great deal more. Simply because those outside fibres are packed a lot thinner and a lot tighter. Then the wind and the elements can dry the moisture on the outside of the fabric. “The nature of fabric and the way that threads are woven means that we don’t have to physically laminate two layers of fabric with a glueing or heat process.

When you make a fabric you can change the gradient of the fibre as you move to the outer surface. So it’s just a matter of mixing in the thinner threads with the thicker threads, and in some cases in the very high end garments you might have a medium thread in the middle as well, to really enhance that movement. “The thickness of a jersey would be around three millimetres and shorts around two millimetres. A lot of that space is air space. “This engineered fabric has an inside and an outside, so it has to be orientated the right way. There’s not that much engineered fabric available, but it has been used for some time in the outdoor industry and the high end of the cycling industry. “It would be hard to give an accurate figure but I would say the top 15% of cycling garments from high end and niche brands would be using those technologies. When you get into alpine sportswear, they’re totally reliant on their garments to keep them alive, so the proportion of engineered fabrics gets a lot higher. “There are some other alternatives to get this effect less expensively. For example they’ll spray a chemical to the outside of a fairly plain fabric. That chemical, a little bit like the plastic in a disposable nappy, will suck the moisture to itself. The disadvantage is that it has a quick saturation point, and because this chemical wants moisture attracted to it, then it doesn’t’t want to let it go either. Once you saturate the outer fabric it won’t let it dry into the atmosphere as well as a standard fabric will. “In the long term you’ll eventually wash those chemical treatments away and they’ll no longer work.”

Cut

“The stitching and fabrication of a garment makes up a larger proportion of the cost than the actual fabric. Although we’re talking about very expensive fabrics in some cases, how many panels, how you stitch those panels, including the type of stitching that you use, becomes an expensive labour process, even though a lot of labour is done offshore. “By using a good fabric, but then using a basic cut pattern, you may not get the performance that you’d get otherwise, but you’d get a lot cheaper garment than if it was cut well. “The advantages of cutting well, in a garment meant for cold weather is that you won’t be letting air into places that it shouldn’t get.

From a cycling point of view, fabric that is loose and allowing a lot of air space around the body, whether it

’s an aerodynamic issue or not, that airspace translates to more area you have to warm up. When you’re talking about a hot weather environment, that airspace will overheat, and not allow the performance fabric to do what it’s designed to do and move the sweat away from your body. “So having a neat fit is a lot more important than just being aerodynamic. “On top of that, having fabric that doesn’t

’t bunch is important. For example, if you have a bunching seam between your legs in a short, that can be very uncomfortable. On areas like your elbows and other joints, it can still be uncomfortable. “To avoid that, good garments have ‘pre articulated joints’. For example, forming shorts and jerseys with a curve to follow the body’s contours, so that we’re not relying on cheap fabrics like Lycra to simply stretch and mould the body, but rather pre articulating a better quality fabric. “What you’ll see generally is a lot more panels, including panels in wrists and elbows. “Every time you add a panel, you’re adding cost to the manufacture of the garment.

It’s obviously contributing to why some of the high end garments seem so much more expensive than the low end. “It’s a lot more than just the number of panels. The stitching itself is also an issue. A lot of terms get thrown around such as ‘flat lock stitching’. The truth is that you can use those terms for many different quality levels. Some flatlock stitching is not as good quality as a standard blind stitch. You can have flatlock stitching that is just a ‘visual flatlock’ where they’re stitching a broad area, but with single needlepoint entry on both sides of the fabric that they’re bringing together. “The real purpose of flatlock stitching is to spread the stress of the stitch. A true flatlock will have on any axis, multiple entries of the needle on each side of the fabric that you’re bringing together. So instead of one thread per side, you might have three threads per side, which is bringing the stress on that seam down to a third of what it would be otherwise. “The more you do that, the more cost it adds, because it takes a lot more cotton, more stitching and it takes a lot longer to run it through the machine. “True flatlock stitching was invented originally for military purposes with canvas and things like neoprene where you have a high stress on a seam.”

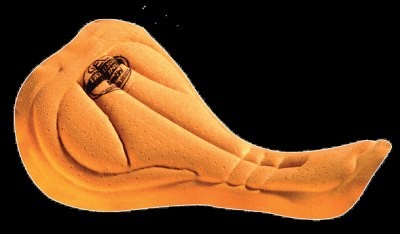

Chamois

Next we spoke to Bernard Schreiber, co proprietor of Queensland base cycle clothing manufacturer, Scody. Bernard has been a passionate researcher in pursuit of the ultimate chamois. As anyone who has ridden a bike will know, comfort in the sitting area can make or break your enjoyment of cycling. The word chamois (pronounced ‘shammee’) is defined as soft, pliable leather from a sheep, goat or deer, but these days, synthetic chamois are far more comfortable and have taken over the market from the animal based versions which used to be all you could buy. Before we hear from Bernard, you should be aware of one final tip. Cyclists don’t wear underpants under their cycling knicks.

The chamois needs to sit next to your skin to do its job. “The main purpose of a chamois is to wick moisture away from the skin,” Bernard explained. “While it’s important for you to feel more comfortable, if you had perspiration accumulating between your knicks and the skin, there is an increased risk of chaffing and discomfort. Also when you have perspiration next to the skin, the muscles heat up to expel the perspiration and that increases fatigue.

“Moisture transfer is a firstly function of the cover fabric. The fabric that sits next to your skin needs to be very effective at transporting moisture. I think the oldest and most recognised moisture transport fabric is CoolMax. There are a lot of new fabrics coming out that do this particularly well. Cheaper fabric has a chemical treatment, which promotes wicking of moisture, more expensive fabric has a special weave to transport moisture. A chemical coating has limited life, but if the fabric is designed and woven to draw moisture away, it is going to last longer and be more effective. “Of course once the cover fabric has taken moisture away, it needs to go somewhere, so the next layer is the foam used in the chamois. It has to facilitate the continued transport of that moisture. On better chamois, they drill holes in the foam to create a channel for the moisture to seep out through the foam and to the outside skin of the garment so it can evaporate. “If you use a cheap chamois for a long period of time it will start absorbing moisture and will become like a sponge. Whereas you can use a good one for many hours and it will never have moisture build up. That is the function of both how the foam is treated and the fabric that gets put on top of it. “A simple test is to wash them and see how quickly they dry. A really good chamois will dry quickly; a cheaper one will take a lot longer. “If you want a chamois to last, you need a backing fabric on the underside of the foam. Of course that backing fabric also has to transport moisture. If you just have open foam straight onto a Lycra, it would tend not to last as long. “There are two things to consider regarding foam. One is the density of the foam, that’s how soft or hard it is. The other is how thick it is. You tend to find that the highest density of foam, in other words the ones that are a little bit stiffer, tend to be better for long rides, whereas the softer foams are good perhaps up to three hours of riding.

“In terms of how the chamois is designed, there are two areas that need protection. One is the perineum area through the middle, the other bit is the ischium area, where the ‘sit bones’ contact the saddle. If you tend to sit forward on the saddle you would probably favour a chamois that was perhaps thinner and stiffer because you don’t need that foam protection on your tailbone. Whereas if you tend to sit back on your sit bones then you probably want thicker foam that will give you more protection on the seat. “There is a difference between ladies and men’s chamois and it’s all to do with the perineal area. Typically a chamois designed for men will have a privacy pad coming up the front. “When you look at a chamois, look for fewer seams. They use bonding techniques to stick everything together rather than sewing it together, because if you have seam you increase the risk of chaffing. If you look at the more expensive ones, they will go right to the top of the privacy pad without any seams at all. Whereas the cheaper ones tend to have a seam between the privacy pad and the chamois. “You also often hear people talking about a four way stretch. It is important that the chamois can stretch, so that it moves with the body and of course with the Lycra of the nicks. If you had a very rigid chamois like the old leather ones, they wouldn’t stretch at all, so you tended to get a little bit more body movement across the chamois rather than the chamois moving with you.

“You stretch the Lycra a little bit before you sew, so that after it’s sewed it’s pretty tight over the chamois. There are different sewing techniques and the most common is a zig zag around the perimeter. “Because of where they sit, chamois need to be antibacterial. “Cheaper chamois have an antibacterial treatment, which will last anything from 10 to 50 washes. More expensive ones typically have silver woven through the fabric, at a nanotechnology scale. You can’t see it, but you don’t have to see it to have it there working. Silver has antibacterial properties. You’ll also find this with carbon and there are new ways people are coming up with all the time to get this permanent antibacterial property. “Our chamois come from TMF in Italy. TMF are happy to do joint research with us. We’ve been doing a lot of research on gel, particularly in triathlon chamois and at the moment we haven’t been getting the results that we are hoping for. One of the reasons of course is that a gel cannot wick moisture.

“You stretch the Lycra a little bit before you sew, so that after it’s sewed it’s pretty tight over the chamois. There are different sewing techniques and the most common is a zig zag around the perimeter. “Because of where they sit, chamois need to be antibacterial. “Cheaper chamois have an antibacterial treatment, which will last anything from 10 to 50 washes. More expensive ones typically have silver woven through the fabric, at a nanotechnology scale. You can’t see it, but you don’t have to see it to have it there working. Silver has antibacterial properties. You’ll also find this with carbon and there are new ways people are coming up with all the time to get this permanent antibacterial property. “Our chamois come from TMF in Italy. TMF are happy to do joint research with us. We’ve been doing a lot of research on gel, particularly in triathlon chamois and at the moment we haven’t been getting the results that we are hoping for. One of the reasons of course is that a gel cannot wick moisture.

“Where you have the gel you have no moisture transport. The cover fabric will take it away but then it’s blocked. So what you find is, particularly in Ironman events, people that are using the gel inserts are complaining that the chamois is getting more sponge like towards the end of the run.”

Artistic Design

Felicity Dales founded Body Torque almost two decades ago. Body Torque designs and manufactures its clothing in Ocean Grove, Victoria. Felicity has a keen eye for fashion, and explained the process that goes into designing a new season’s range. “We do research on what’s happening globally with colour trends,” she said. “What’s going on with mainstream fashion? Which colours are coming in for the season? “Then we look for themes. We create colour palettes and story boards and then work from that. “We combine different colours and design features. With the process of sublimation printing, it allows you to have lots of variety. The sky’s the limit really, depending upon your imagination. “For this year we’re finding that lemon is a big trend for women’s clothing and also a coral colour. “Knicks have moved away from previously being perhaps 90% black to now perhaps 70% being black, with the rest being in another colour or a printed pattern to match the jersey. “Regarding other features like zips, that’s a personal preference.

We tend to do an invisible zip so the design is not interrupted across the front of the jersey, but if the client prefers an open ended zip, we do that as well. “Also we offer sleeveless jerseys or little cap sleeved jerseys for the women. People prefer to have those tan lines not so visible when they’re wearing other clothing. That’s a more recent trend.”

Anatomic Function

Connie Bof (nee Giramondo) has literally spent her entire life in her family’s clothing business, Giramondo Sportswear, which was founded by her father, professional cyclist Mario Giramondo, in 1958. She grew up in the sewing room watching her mother and others making cycling clothing. “Anatomical cut is important,” Connie said. “If you’ve got a good fit, you’re going to be comfortable and you’re going to enjoy what you’re doing a lot more. “For example the fabric should be cut on the diagonal, so that you get four way stretch, for comfort. With all fabrics there is a warp and a weft. Warp refers to the lengthways yarns and weft is the yarn that is threaded back and forth between the warp. The weft direction has more stretch than the warp. “If you place your pattern on the diagonal of those two, you will get maximum four way stretch. “We waste a lot more fabric doing it that way, (because you can’t fit as many pattern pieces per metre of fabric) but you get a better garment.

Sometimes people are selling eight panel shorts, but if they have not laid their pattern on the fabric in this way, it’s not going to make a truly contoured garment. “We make most of our jerseys with a raglan cut for the sleeves. These contour your shoulders to give you ease of movement. A raglan is where the top panel of the sleeve comes up to the neckline at the collar. The other style is the set in sleeve, which is more of a tailored fit. “We source a lot of our high tech fabrics from Europe, obviously because they’ve got a bigger cycling market there, but we do buy Australian made fabric as well.” As you can see from these four Australian experts, there is a lot more design and thought that goes into cycle clothing than you might initially think. If space had permitted it, we could have spoken to more than a dozen other companies, who are also offering great products to the Australian market. As a cyclist, your choice has never been greater and garment function and fit has never been better. Even if you can’t ride like the pros, at least you can dress as comfortably, and look the part too!

From a cycling point of view, fabric that is loose and allowing a lot of air space around the body, whether it’s an aerodynamic issue or not, that airspace translates to more area you have to warm up. When you’re talking about a hot weather environment, that airspace will overheat, and not allow the performance fabric to do what it’s designed to do and move the sweat away from your body. “So having a neat fit is a lot more important than just being aerodynamic. “On top of that, having fabric that doesn’t’t bunch is important. For example, if you have a bunching seam between your legs in a short, that can be very uncomfortable. On areas like your elbows and other joints, it can still be uncomfortable. “To avoid that, good garments have ‘pre articulated joints’. For example, forming shorts and jerseys with a curve to follow the body’s contours, so that we’re not relying on cheap fabrics like Lycra to simply stretch and mould the body, but rather pre articulating a better quality fabric. “What you’ll see generally is a lot more panels, including panels in wrists and elbows. “Every time you add a panel, you’re adding cost to the manufacture of the garment.

From a cycling point of view, fabric that is loose and allowing a lot of air space around the body, whether it’s an aerodynamic issue or not, that airspace translates to more area you have to warm up. When you’re talking about a hot weather environment, that airspace will overheat, and not allow the performance fabric to do what it’s designed to do and move the sweat away from your body. “So having a neat fit is a lot more important than just being aerodynamic. “On top of that, having fabric that doesn’t’t bunch is important. For example, if you have a bunching seam between your legs in a short, that can be very uncomfortable. On areas like your elbows and other joints, it can still be uncomfortable. “To avoid that, good garments have ‘pre articulated joints’. For example, forming shorts and jerseys with a curve to follow the body’s contours, so that we’re not relying on cheap fabrics like Lycra to simply stretch and mould the body, but rather pre articulating a better quality fabric. “What you’ll see generally is a lot more panels, including panels in wrists and elbows. “Every time you add a panel, you’re adding cost to the manufacture of the garment.

“You stretch the Lycra a little bit before you sew, so that after it’s sewed it’s pretty tight over the chamois. There are different sewing techniques and the most common is a zig zag around the perimeter. “Because of where they sit, chamois need to be antibacterial. “Cheaper chamois have an antibacterial treatment, which will last anything from 10 to 50 washes. More expensive ones typically have silver woven through the fabric, at a nanotechnology scale. You can’t see it, but you don’t have to see it to have it there working. Silver has antibacterial properties. You’ll also find this with carbon and there are new ways people are coming up with all the time to get this permanent antibacterial property. “Our chamois come from TMF in Italy. TMF are happy to do joint research with us. We’ve been doing a lot of research on gel, particularly in triathlon chamois and at the moment we haven’t been getting the results that we are hoping for. One of the reasons of course is that a gel cannot wick moisture.

“You stretch the Lycra a little bit before you sew, so that after it’s sewed it’s pretty tight over the chamois. There are different sewing techniques and the most common is a zig zag around the perimeter. “Because of where they sit, chamois need to be antibacterial. “Cheaper chamois have an antibacterial treatment, which will last anything from 10 to 50 washes. More expensive ones typically have silver woven through the fabric, at a nanotechnology scale. You can’t see it, but you don’t have to see it to have it there working. Silver has antibacterial properties. You’ll also find this with carbon and there are new ways people are coming up with all the time to get this permanent antibacterial property. “Our chamois come from TMF in Italy. TMF are happy to do joint research with us. We’ve been doing a lot of research on gel, particularly in triathlon chamois and at the moment we haven’t been getting the results that we are hoping for. One of the reasons of course is that a gel cannot wick moisture.